Diamond: Shaping the Future of Cookware

Diamond stands as one of the most remarkable materials on Earth. It is the hardest naturally occurring substance, rating 10 on the Mohs scale, and offers exceptional thermal conductivity, optical properties, and durability.[1][2][3][4] These qualities are now being harnessed in cookware to provide a better cooking experience. diamondPans has taken a leading role in this innovation, delivering a product that is both high-performing and responsible, meeting the evolving needs of today’s consumers.

Why Diamond Cookware?

Diamond’s superior thermal conductivity, approximately 20 W/cm·K, allows heat to spread quickly and evenly across the cooking surface.[2][3][4] This uniform heat distribution helps eliminate the common problem of hot spots, enabling more precise temperature control. Whether you’re sautéing vegetables, searing a steak, or simmering delicate sauces, the consistent heat transfer provided by diamond surfaces can lead to tastier, more evenly cooked meals.

Health and Environmental Considerations

Concerns have grown over traditional non-stick coatings that may contain harmful “forever chemicals” like PFAS, which can persist in the environment and potentially pose health risks.[5][6][7] In response to these issues, consumers are increasingly seeking safer alternatives. diamondPans addresses these concerns by eliminating these harmful chemicals, thereby offering cookware that is both safer for your family’s health and more considerate of our planet’s well-being.[9] By using real diamonds firmly attached to the pan’s surface, rather than chemical-based coatings, diamondPans ensures that nothing harmful is released into your food or the environment.[9][10]

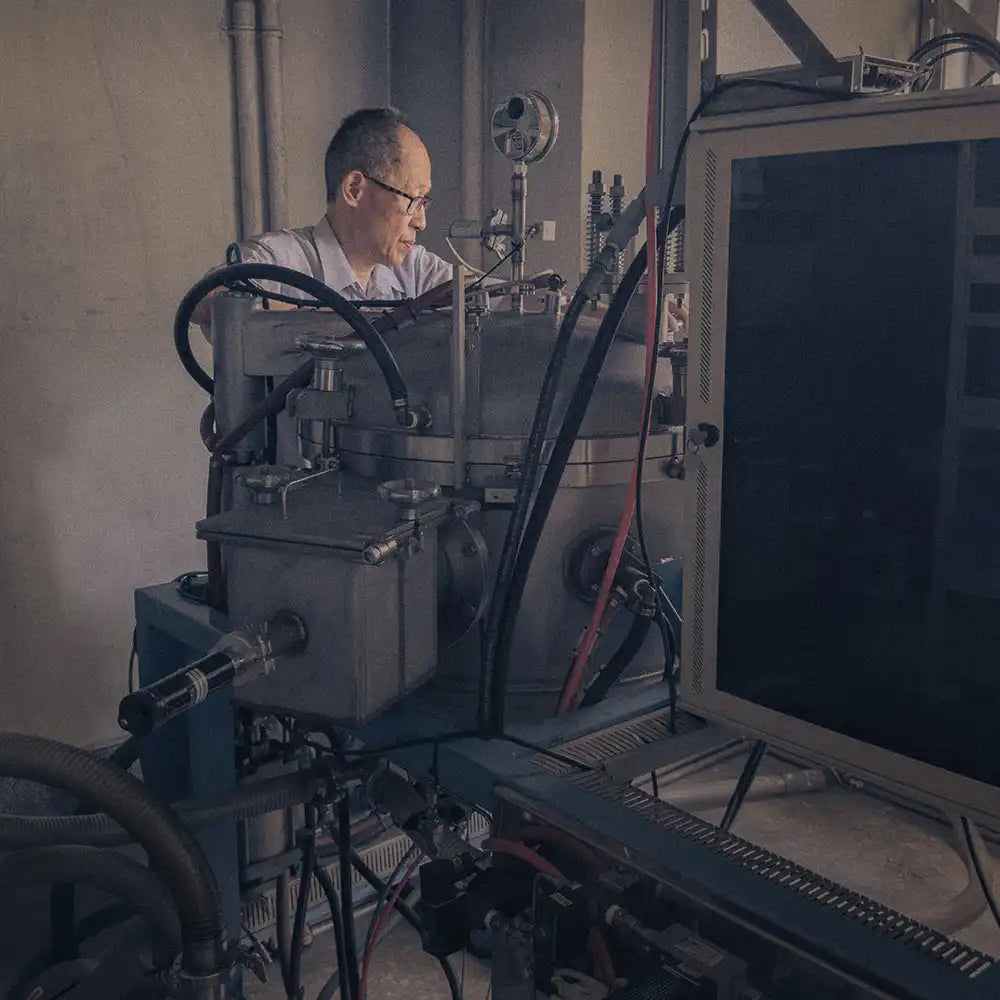

A Different Approach: Real Diamonds, Vacuum Brazed

Instead of relying on sprayed-on coatings or infused diamond particles that may wear down or release unwanted substances over time, diamondPans employs a vacuum brazing technique. This method permanently bonds sixty carats of real diamonds directly onto the cookware’s surface, ensuring that the diamonds remain securely in place, even after years of intense use.[9][10] Because the diamonds are physically affixed rather than embedded in a coating, there’s no risk of them coming loose, flaking off, or leaching contaminants into your meals. The result is a naturally clean, durable, and reliable surface that stands the test of time.

Why Vacuum Brazing Is Better Than Other Methods

Other cookware brands may rely on coatings or “infusing” processes to incorporate diamond particles. These methods can involve chemical binders, layers that degrade, or particles that are merely mixed into the surface rather than structurally bonded. Over time, such coatings can wear down, and microscopic particles may be released into your food or the environment. By contrast, diamondPans uses vacuum brazing to fix real diamonds onto the pan’s surface without additional chemical layers. This direct bonding process creates a stable, long-lasting, and inherently non-stick cooking surface that does not rely on additives that could fail over time. Vacuum brazing ensures that the cookware’s diamond surface remains intact, safe, and effective throughout its lifespan.

Durability, Longevity, and Sustainability

The diamond layer’s unparalleled hardness and resilience provide significant advantages in terms of durability and longevity. A pan made with this method resists scratches and maintains its performance, helping you avoid frequent replacements.[5][7] Reducing the need to buy new cookware saves resources, minimizes waste, and aligns with sustainable consumer values. In a growing global market—expected to reach new heights in the coming years—consumers are looking for reliable products that withstand daily use while also being kinder to the environment.[8][9]

Evolving Market and Ethical Choice

As consumer preferences shift towards safer and more sustainable kitchenware, diamondPans leads by example. By utilizing real diamonds securely bonded to the pan through vacuum brazing, they’ve created a solution that outperforms traditional coatings or diamond-infused alternatives. This innovation responds to changing market demands, supports responsible production, and reflects a commitment to leaving a lighter environmental footprint.[9][10]

Conclusion

diamondPans demonstrates that superior cooking performance, health considerations, environmental responsibility, and product longevity can go hand in hand. By leveraging diamond’s unique thermal properties and employing a vacuum brazing technique to bind real diamonds directly to the cookware surface, diamondPans offers a forward-thinking alternative that stands apart from conventional materials. This approach not only ensures exceptional cooking results but also provides peace of mind for consumers who care about their health, their meals, and the world around them.

References

- Principal Properties of Diamond - University of Bristol

- Solids, Liquids and Gases - Thermal Conductivities, The Engineering Toolbox

- Material Properties of Diamond - Wikipedia

- Diamond – Density – Melting Point – Thermal Conductivity, Material Properties Online

- The Sparkling Truth About Diamond Cookware Sets: A Comprehensive Review, The Cooking Facts

- Uncovering the Truth: Is Diamond-Infused Cookware Safe for Your Kitchen? Kitchen Analysis Report

- Diamond Cookware (Is This Worth The Hype?), The Kitchen Eye

- Cookware Market Size, Share, Growth Analysis Report, 2030, Market Research Future

- Diamonds for a Cleaner Future: The threats of PFAS

- From Accident to Innovation: World first diamond crystals cookware