Vacuum Brazed vs. Diamond-Infused Cookware: The Guide to Choosing High-Performance Kitchen Tools

Vacuum Brazed Diamond Cookware

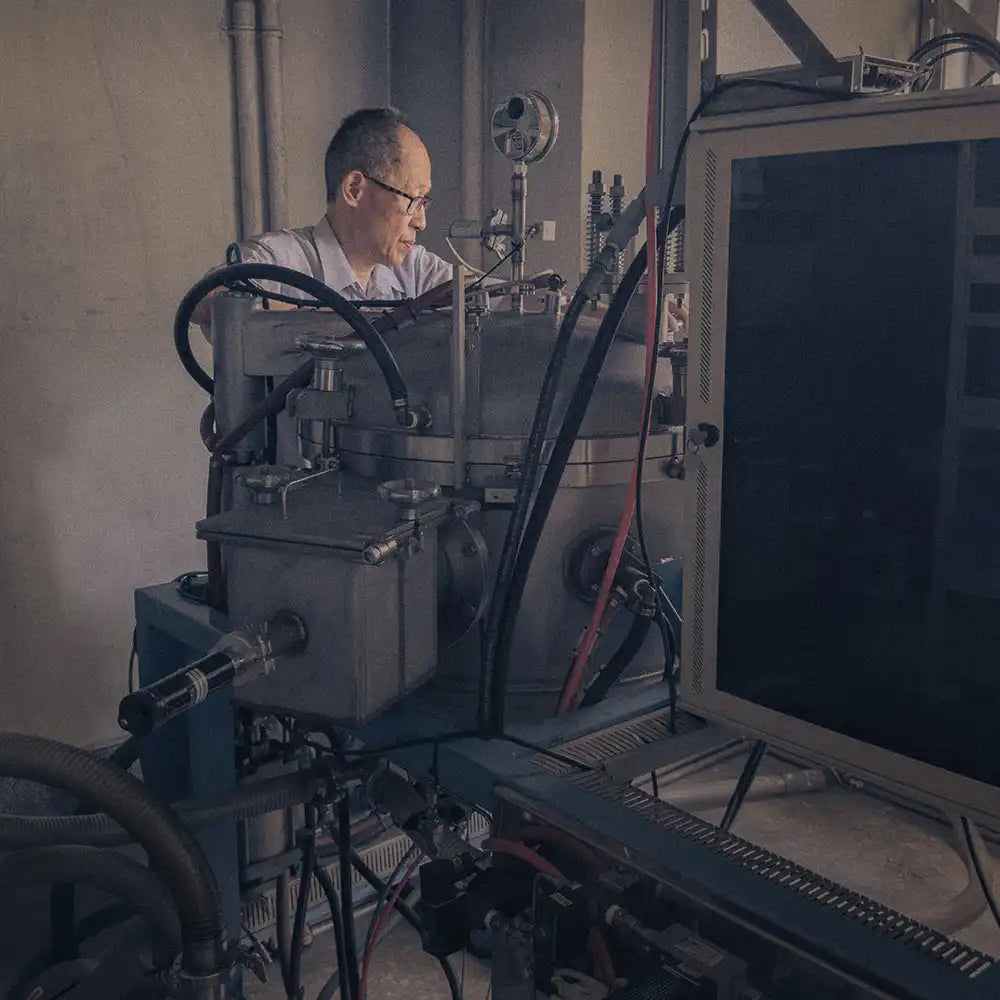

Vacuum brazed diamond cookware is produced using an advanced high-temperature bonding process in a controlled vacuum environment. During manufacturing, diamond particles are mixed with a brazing material and heated until the brazing material melts and permanently fuses the diamonds directly onto the cookware’s surface. This approach ensures a robust, uniform, and long-lasting bond.

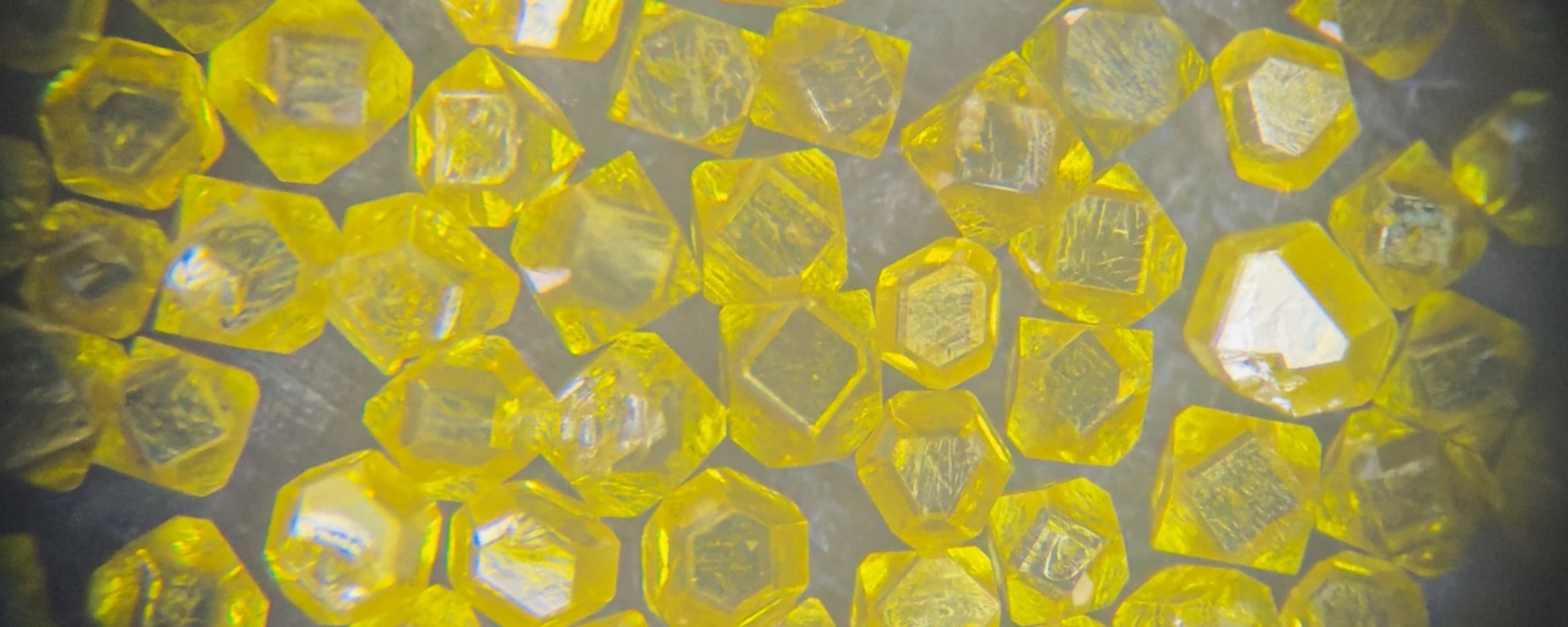

Because the diamond particles are not merely coated onto the surface but are instead integrally brazed, this cookware exhibits exceptional hardness and edge retention. These properties make it particularly effective for tasks that require intense durability, such as cutting, grinding, or working with very hard materials like ceramics, granite, and other non-ferrous substances.[1][2][3] The surface is highly scratch-resistant and capable of maintaining its integrity even under heavy use and high temperatures. Additionally, vacuum brazed cookware excels at heat distribution and thermal conductivity, promoting efficient and uniform cooking.[2][3]

Some vacuum brazing processes involve melting a specialized CuSnTi alloy around diamond crystals, ensuring the diamonds remain securely affixed to the cookware’s surface and forming a single, durable layer of diamond particles.[11]

However, these advantages come at a price. Vacuum brazed diamond cookware tends to be more expensive than conventional non-stick or ceramic-coated options. While it may offer superior long-term value due to its lifespan and resilience, the initial investment can be a deterrent for some consumers.[5][12] Moreover, although designed to provide a non-stick experience, proper maintenance—such as using moderate amounts of cooking oil and following recommended cleaning techniques—may be required to ensure consistent, non-sticking results.[5][6]

Diamond-Infused Cookware

Diamond-infused cookware, on the other hand, integrates diamond particles into a non-stick coating, typically a ceramic matrix. This process aims to enhance durability, heat tolerance, and scratch resistance compared to traditional non-stick surfaces. The term “diamond-infused” can be somewhat misleading; rather than having large diamond structures embedded, the cookware usually contains fine diamond particles dispersed within the coating to improve overall performance.[6][7][8]

The primary appeal of diamond-infused cookware lies in its promise of healthier cooking, greater resistance to wear, and improved heat conductivity. Many formulations claim they can handle higher temperatures without breaking down, thus mitigating some concerns over coating degradation. Diamond infusion also aims to strengthen the non-stick surface, making it more resistant to scratching or flaking than standard coatings.[1][2][5]

Despite these claimed improvements, diamond-infused cookware may not always live up to the marketing hype. In practice, while it may show better durability than simple ceramic or PTFE coatings, it often does not match the structural robustness of vacuum brazed diamond cookware. The diamond particles are incorporated into a layer that can still wear over time, especially with improper care, rough handling, or abrasive cleaning methods.[8][9] Critics have also raised questions regarding the potential for chemical leaching or particle release if the coating degrades.[8][9] Another concern is that the “diamond-infused” label may primarily serve as a promotional term rather than indicating a fundamentally transformative cooking surface.[6][7]

Why Vacuum Brazed Diamond Cookware is Often Considered Superior

When comparing the two, vacuum brazed diamond cookware generally stands out for its direct bonding of diamond particles onto the metal surface. This results in a more stable and long-lasting construction that can handle demanding conditions. Its superior resistance to scratching, chipping, or peeling makes it ideal for tasks where tools and utensils with harder edges are frequently used. Additionally, its exceptional thermal conductivity ensures consistent and energy-efficient cooking.[1][2]

While diamond-infused cookware can improve upon standard non-stick products by offering somewhat better durability and heat tolerance, it often cannot match the ruggedness, longevity, and edge retention provided by the vacuum brazing process.[1][4] Vacuum brazed diamond cookware is also better suited for industrial or professional kitchen environments where cookware must endure heavy-duty use, whereas diamond-infused cookware, despite its claims, may not meet these rigorous demands as effectively.[2][3][4]

Considerations for the Consumer

The choice between vacuum brazed and diamond-infused cookware ultimately depends on one’s cooking habits, performance expectations, and budget. Vacuum brazed options may have a higher initial cost but can deliver exceptional longevity, versatility, and performance in both standard and specialized cooking tasks.[1][2][5] Diamond-infused cookware, though potentially more affordable, might offer only incremental improvements over traditional coatings and can still face issues related to long-term durability and coating integrity.[6][8][9]

In essence, vacuum brazed diamond cookware represents a significant technological advancement that provides a stronger, more heat-efficient surface and greater resilience under challenging conditions. These qualities often justify its reputation as a superior choice compared to diamond-infused cookware for those who prioritize durability, performance, and long-term value.

References

- Essential Tips for Using Vacuum Brazed Diamond Blades Effectively

- Sintering vs. Vacuum Brazing vs. Electroplating, What are the ...

- Brazing diamond - SIMUWU Vacuum Furnace

- How are vacuum brazed diamond tools made? - More Super Hard Products Co ...

- Advantages and Disadvantages of Vacuum Brazing - Listemann

- Uncovering the Truth: Is Diamond-Infused Cookware ... - Flavory Cooking

- Diamond Cookware (Is This Worth The Hype) - The Kitchen Eye

- How Brazing Diamonds Works & Vacuum Brazing Solutions

- 21 Pros And Cons Of Blue Diamond Cookware

- Cooking with Confidence: Uncovering the Truth About Blue Diamond ...

- Vacuum brazed diamond cookware